Signco America Chooses Tetra® Snap Modules for Cabinet Sign Project

Signco America Chooses Tetra® Snap Modules for Cabinet Sign Project

The Opportunity

Based in Houston, Texas, Signco America is an industry-leading fabricator of custom signage, architectural elements and large-format graphics in the Southwest region. Founded in 1980 as Sparkle Sign, Signco became a big name in the neon world, recognized as experts in the art of manufacturing and assembling neon for projects big and small.

“Our expertise has expanded greatly over the past 40 years,” said Signco’s CEO Joe Minavi. “We have become one of the best in the nation in terms of knowing how neon and also LED lighting can be used for signs of all sizes.”

Signco’s 40-plus years of signage design expertise, along with their high level of dedication to their clients, is why American Furniture Warehouse (AFW), a major American home decor and furniture chain, approached Signco about creating a series of double-faced cabinet signs for three new Southeast Texas locations.

Minavi and the rest of his Signco team were up for the challenge and got to work designing and fabricating the cabinet signs at their shop. To make sure they popped, they needed a bright LED module that could easily be customized for the different sections of the sign.

The Solution

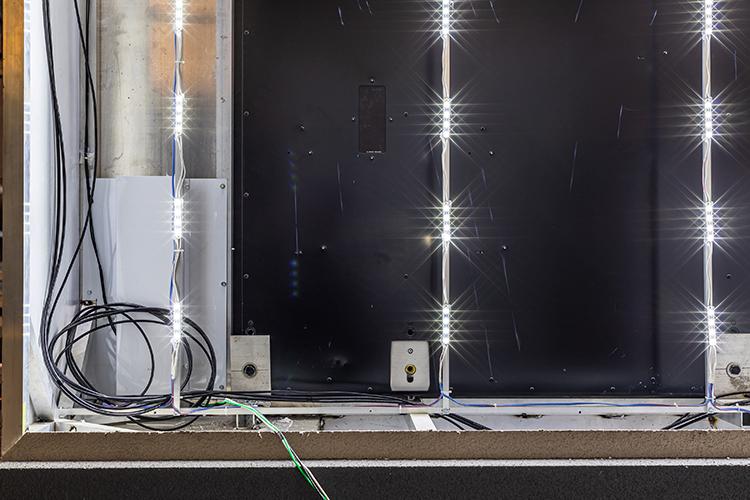

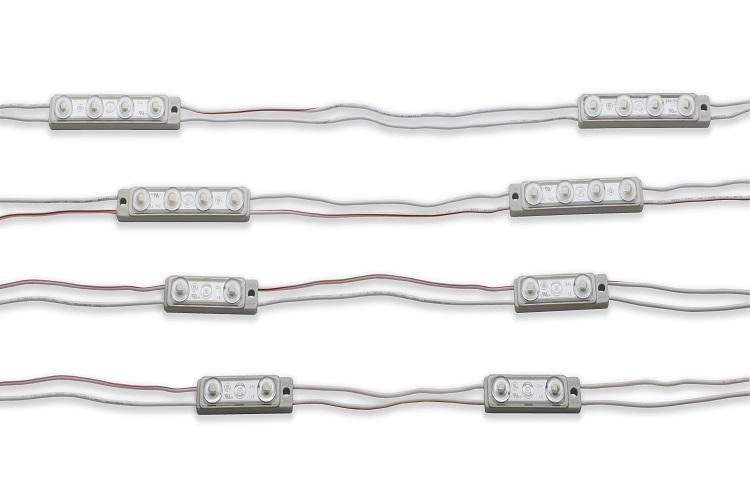

Having used Tetra® MAX successfully in the past, Signco once again turned to Current for an LED lighting solution that best fit AFW’s monument signs. To complete this multi-shelf installation, Signco employed both the single-sided and double-sided versions of the Tetra Snap, as both were needed due to the signs’ specific design. The Snap was chosen for this project because of the product’s flexibility, which is the result of its unique design. The modules simply snap into an aluminum rail and can be custom-spaced for on-the-fly brightness adjustment. The Snap was the perfect solution for the double-sided sections at the top of the signs, and the single-sided sections at the bottom.

One of the most important benefits of Tetra Snap for Minavi is its impressive loading numbers: one power supply powers 32 double-sided modules to up to 1000 lumens per foot.

“We used it because we wanted one sign to only have one power supply, as opposed to two or three. Using more than one creates more potential points of failure, requiring more maintenance,” said Minavi. “So that is what we have been doing, and we’ve been very successful in creating reliably-lit signs for our clients.”

The Results

Signco installed all three large monument signs, with Tetra Snap illuminating the entire sign. The upper cabinet of the sign is double-sided, lit by Tetra Snap DS, and the bottom cabinet uses the new Tetra Snap SS modules. The lit portion of the signs are 4’ by 11’, with an electronic LED message board underneath.

Most importantly, by using the Tetra Snap system, Signco was able to cut labor costs by 50% due how much quicker Snap is to install than competing systems: no screws, no silicone and no measuring required.

“It’s all about cutting the cost of labor while not laying off any employees. It’s important to me that I keep the employees that have been with me for a while,” said Minavi. “That has always been my philosophy—find a solution that can help us cut the amount of labor with the product or with the equipment.”

Learn more about how Tetra LED systems can provide significant energy cost reductions, easier job site installation, less frequent maintenance and more consistent brightness to your next signage project.